Custom Schoolhouse Light

Role: Industrial Design, Engineering, Sourcing.

Problem: Our client, a major theme park, tasked us with creating a new fixture to replace an old one. The old fixture looked out of place visually breaking the environment, so the client requested a schoolhouse style with antique brass fitter.

Challenges: The fixture we were replacing ran on 277v as part of their emergency lighting system. They only wanted three units making it cost prohibitive to build from scratch and get UL certification. The challenge was sourcing an off-the-shelf fixture and an off-the-shelf plastic schoolhouse globe that could fit over the fixture.

Design: I emulated the schoolhouse style with some quick prototypes we mocked up for the client, and was then given the go ahead to start manufacture.

3D printed prototype.

Design selected by client.

Manufacture: Due the very short 1 week time-line, I made the decision to use brass instead of sending out an aluminum part for coating with an antique brass finish. The client also wanted the brightest light we put in, we settled on a 2500lm A21 bulb in 3000K. The warm color temperature was necessary to capture the antique look.

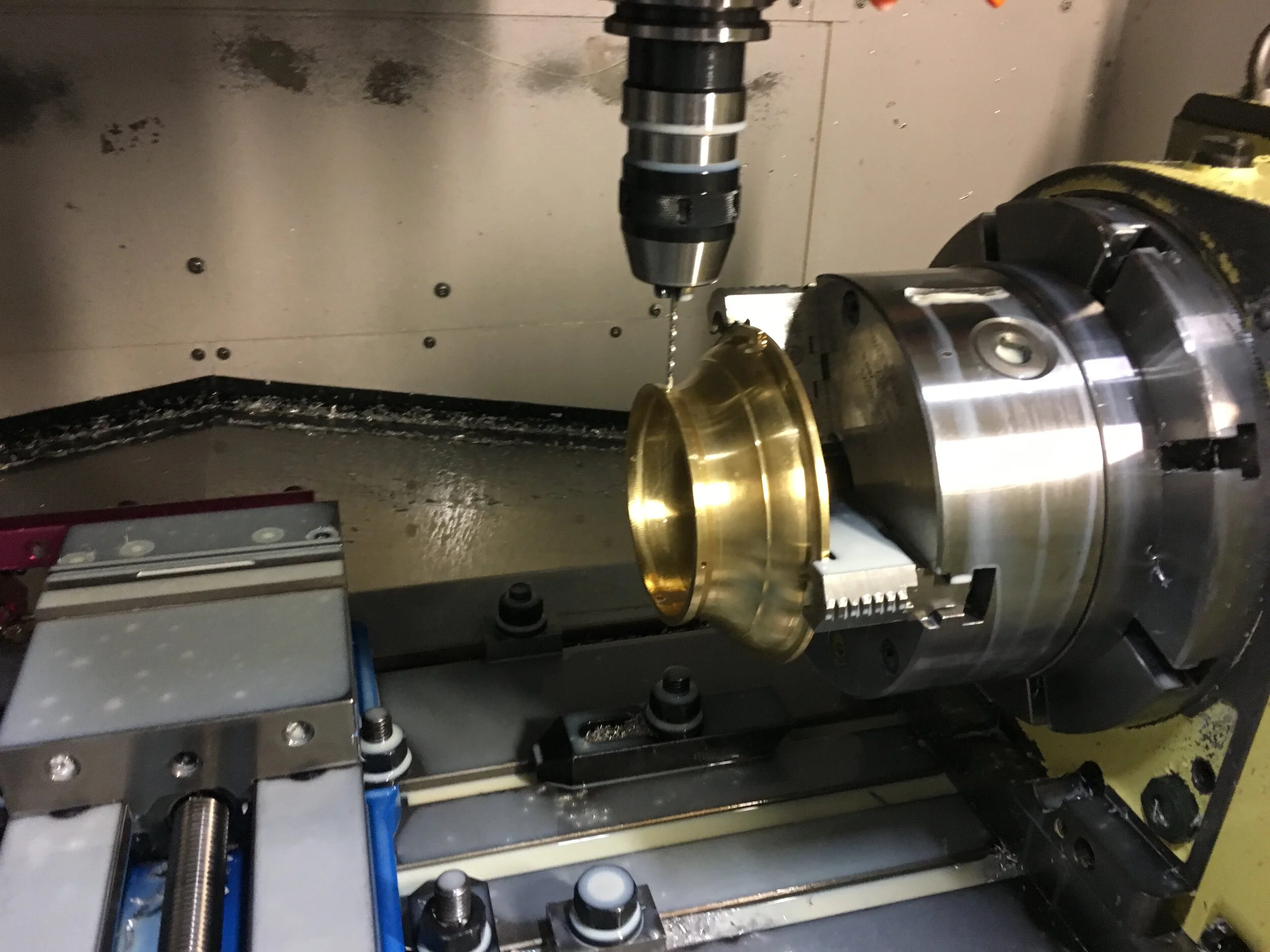

Holes being drilled and taped on 4th axis.

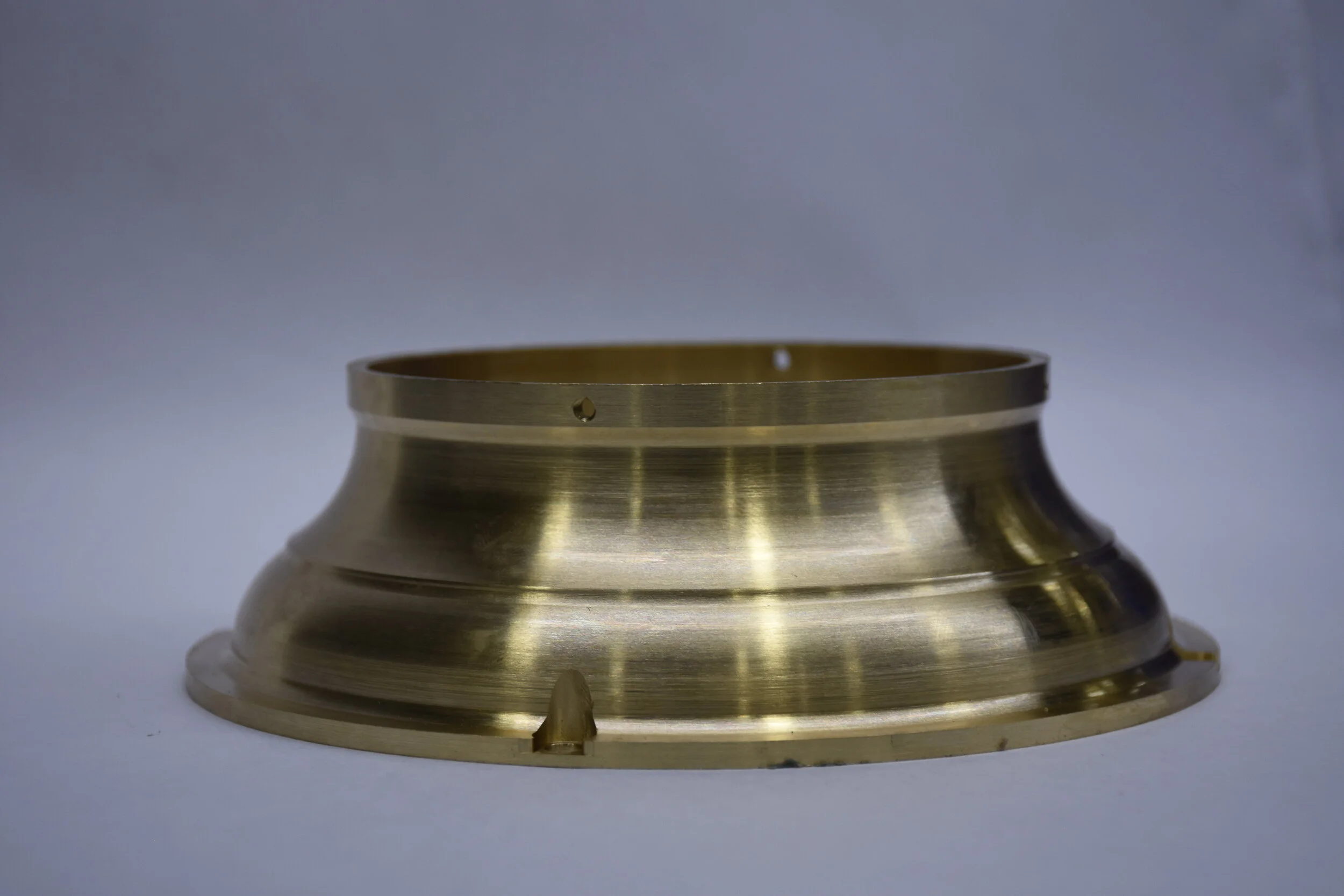

Part before chemical tarnishing.

Fixture installed at location.